Steel

A PEERLESS MATERIAL

High-load bearing capacity and a range of options such as usage, economics, and good recycling properties are among the key factors in selecting modern materials. Vertical load bearing structures, and space enclosing lightweight steel structures, benefit from these qualities of steel and provide a significant addition to the portfolio of materials at our disposal.

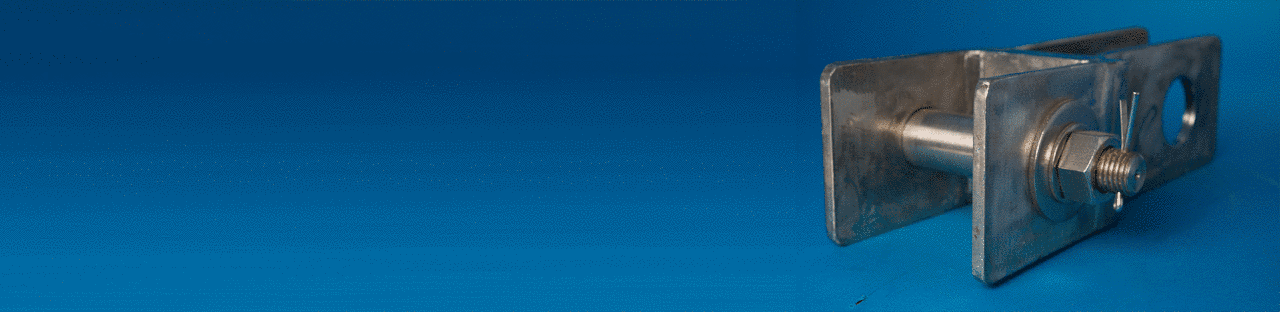

Semi-Finished Products

As a starting material we use semi-finished products made from steel. We use steel rods, steel sections, steel plates, steel pipes, in our production of “intelligent” components. At the outset of the process we optimise the materials to be used for each specific application bearing in mind such factors as cost, availability, formability and durability of the material.

Cast Steel

Cast steel is used for special components and complex forms. Our engineers select the appropriate grade of steel for each specific project and monitor the entire manufacturing process.

Forming

Steel is particularly notable because of the wide variety of forming processes that can be used to produce any one component. A prerequisite of the processing of semi-finished products is possession of the relevant technical skills and essential know-how. Hightex manages and coordinates all aspects of the production process to ensure on-time delivery of projects.

Surface Treatment

Clean surfaces are essential for processes such as coating, flame cutting, laser cutting and welding and to achieve this we use special blasting technology.

Corrosion Protection

Optimal corrosion protection is achieved through a combination of active and passive surface protection that includes the following methods: - Coating of the steel surface with a liquid or powder material - Hot- dip or thermal spray processing - Metallic coating methods (Duplex- Systems).

Inspection

For all steel parts made we carry out a rigorous quality control inspection so as to meet the appropriate standards, including safety. We use objective parameters to ensure that the desired mechanical, thermal, and chemical material properties are met and in this way we consistently evaluate the impact of alternative processing routes.

Lifespan

Long lifespan of steel parts can be obtained provided that the appropriate manufacturing process is utilised and the necessary corrosion protection is applied. Service life is only compromised if the components are damaged during use giving rise to local corrosion.

Environmental Compatibility

No other metal can be recycled as completely, and without loss of material quality, as steel. It is thus environmentally friendly as it conserves both energy and natural resources.

Further Information

For more information please contact us. As a capable and efficient partner we will be delighted to help you.