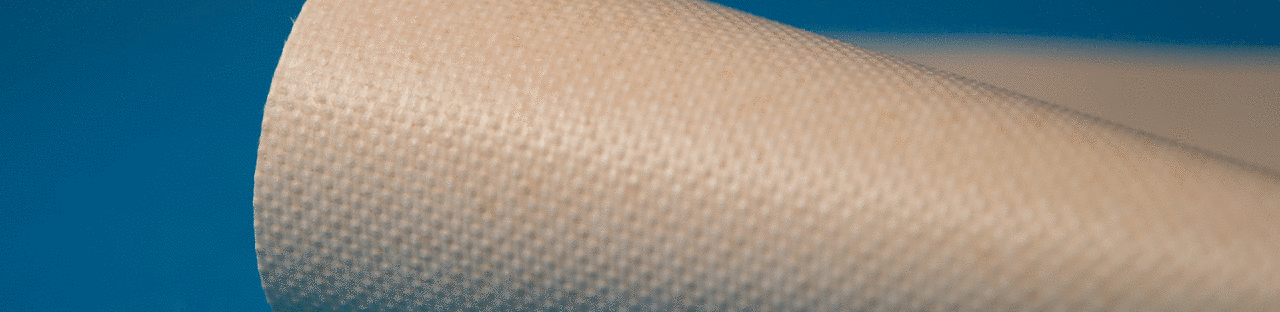

PTFE Glass Fabric

THE "FRONT RUNNER"

PTFE-coated Glass fabric material is a high-grade glass fabric with a protective coating based on fluoropolymer. This material has been used for more than 20 years in the fields of roof, facade and building envelopes resulting in visually stunning architecture.

Fluoropolymers are the highest quality membrane materials in terms of their superior durability, fire rating and visual appearance properties. Furthermore, extremely high strength glass fabrics such as PTFE coated fibreglass allow very large building spans to be created, possess extreme durability in terms of lifespan and with their translucency are seemingly weightless.

Lifespan

PTFE coated fibreglass has a lifespan of approximately 25-30 years and will continue to show an excellent surface appearance after this time. The molecular structure of the coating is considered to be one of the most stable organic compounds and provides an extremely durable material against all known environmental factors.

Fire Classification

PTFE Glass consists out of two nonecombustible materials - fiberglass and PTFE. The resulting composite meets or exceeds the most stringent fire codes throughout the world (according to DIN 4102 classified in fire class A2) Acceptance of PTFE Glass as a permanent roofing material is based on its ability to meet the same tests as any conventional roofing material.

Photometric properties

The beauty of PTFE Glass lies in its superior ability to transmit light. At daytime it is a diffused natural daylight, bringing the open air feeling of color correct light indoors, at night PTFE Glass backlit luminosity creates a dramatic architectural signature to the outside. The translucency of PTFE Glass depends on its thickness and lies between 8% -20%. (A light transmission of 5% offers sufficient daylight conditions to go without artificial light) Due to a special process, PTFE can also be activated with low-E-coating.

Thermal insulation

Multi-layered membrane structures can be provided with excellent thermal properties either through the entrapment of air, or by the insertion of insulating materials that meet the requirements of high thermal insulation building shells. Amongst the recommended materials are translucent nonwoven materials such as PTFE-coated glass so as to retain the light transmission properties of the membrane material as far as possible.

Colors

PTFE Glass is available in a full range of colors, including metallics, colors which will withstand the ravages of time.

Warranty

PTFE-coated glass has outstanding material properties so that a very long warranty can be granted, depending on the project specification.

Environmental compatibility

The collection and recycling of the material's useful life is increasingly standard. Connection systems are sorted recyclable after separating from the membrane. PTFE solar reflectance of around 70% and its thermal emittance of nearly 90% make it the truly quintessential green choice for everybody seeking energy saving products. For valuable LEED points, lower air conditioning and lighting costs, maintenance free attributes and the lightweight of the material with reduction potential in the overall constructions are only a few arguments for PTFE Glass.

Handling

PTFE-coated fibreglass fabrics are joined using the appropriate cutting and thermal impulse welding processes. Our decades of manufacturing know-how and our latest machinery and design software guarantee reliable precision production of high strength and durable welds.

Construction Method

PTFE-coated glass membranes are used in roofing, cladding and building envelope structures with virtually unlimited design possibilities. In the process of installation, the membrane is mechanically pre-stressed. With the tension depending on the precise details of both the installation requirements and the geometry of the membrane. The value of the pretension stress will depend on the curvature of the membrane and many other factors but in no case can the membrane be installed without tension being applied.

Maintenance and Cleaning

Compared to conventional roofs and facades, the maintenance requirements of PTFE glass membranes are extremely low. Inspections are primarily used to locate damage caused by mechanical factors and to prevent further damage. The superior anti-adhesive properties of the coating produce a self-cleaning effect, which prevents the accumulation of dirt and maintains excellent surface appearance. As a result, cleaning is generally not necessary.

Futher information

For more information on PTFE membranes please contact us - as a capable and efficient partner we will be delighted to help you.