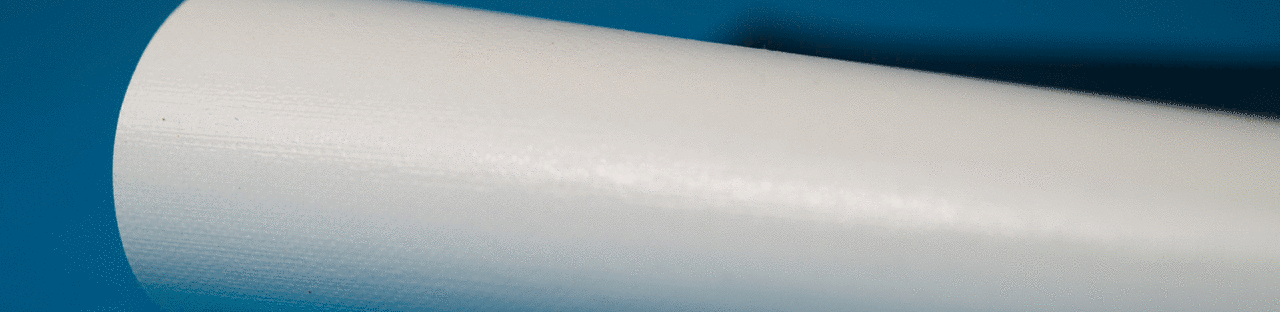

Silicone Glass Fabric

THE FLEXIBLE MEMBRANE

Silicone-coated glass fibre fabric offers a material with an extremely high light transmission combined with a high strength. The fabric is both flexible and kink-resistant and is an alternative to traditional membrane materials.

Silicone glass membranes are impregnated and coated with special transparent silicone fibre fabric. They are characterized by good water vapor permeability, high UV radiation resistance, have an extremely low weight and durability. These materials allow the creation of facades, roof and building envelopes whose elegance and lightness is unique.

Lifespan

With a lifespan of approximately 25 to 30 years the silicone-coated glass fabrics are extremely durable and in addition are very robust being resistant to most environmental agents.

Fire Classification

Silicone glass membranes are incombustible and are classified as B2 (DIN 4102). At high temperatures neither toxic fumes are evolved nor do molten drips appear.

Thermal Insulation

Multi-layered membrane structures can be provided with excellent thermal properties either through the entrapment of air, or by the insertion of insulating materials that meet the requirements of high thermal insulation building shells. Translucent nonwoven materials are recommended in order to obtain the appropriate light transmission properties of the required membrane material.

Maintenance and Cleaning

Compared to conventional roofs and facades the maintenance requirements of these materials are extremely low. Inspections are primarily used to locate damage caused by mechanical causes in order to prevent further possible damage. The material has a stain-resistant coating and this means that cleaning can be performed with simple, biodegradable detergents.

Warranty

The outstanding property of these materials enables a warranty of up to 10 years to be granted, the terms of each individual warranty are a function of each project.

Environmental Compatibility

The collection and recycling of the membrane material at the end of its useful life is now standard practice. The components of connection systems are separated from the membrane and recycled by conventional methods.

Photometric Properties

The translucency of silicone-coated glass membranes depends on their thickness and colour with peak values of up to 35% being recorded. The material is resistent against UV light.

Handling

Silicone-coated glass membranes do not have a fixed melting point and therefore must be vulcanized. These materials are rigorously tested, in particular for their strength, and this guarantees excellent results.

Construction Methods

Silicone-coated glass membranes are often but not exclusively used for interior applications. They can be used as roofing, cladding and building envelope structure. The membranes are suitable for both mechanically and pneumatically pre-stressed installations.

Further Information

For more information on Silicone-coated glass membranes please contact us - as a capable and efficient partner we will be delighted to help you.